UV Sheets

What are UV Sheets?

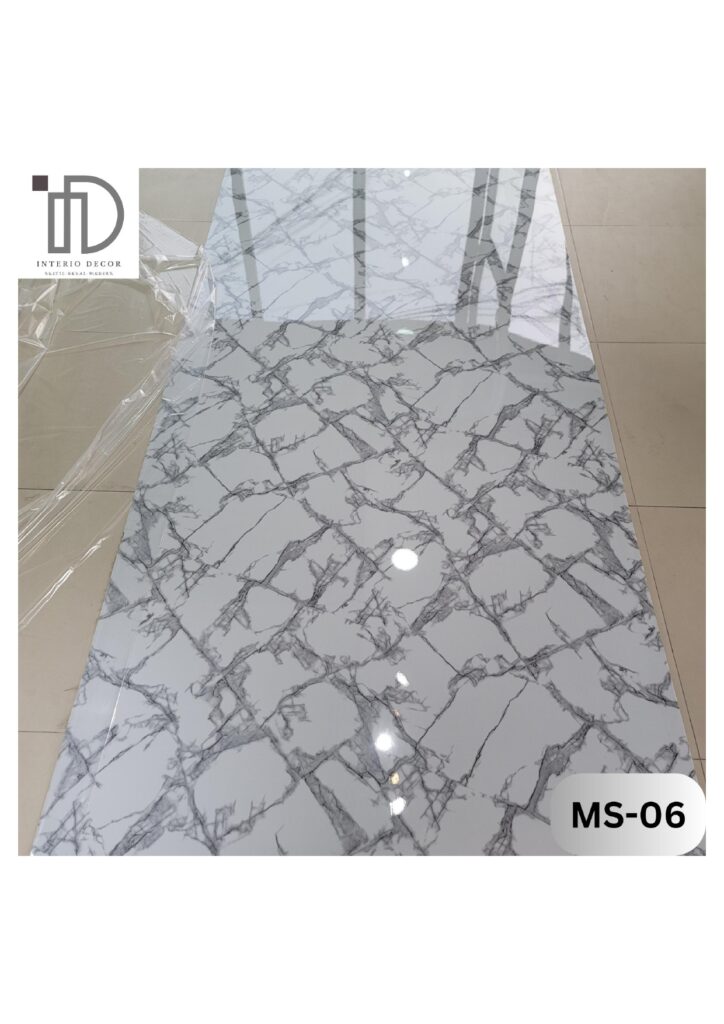

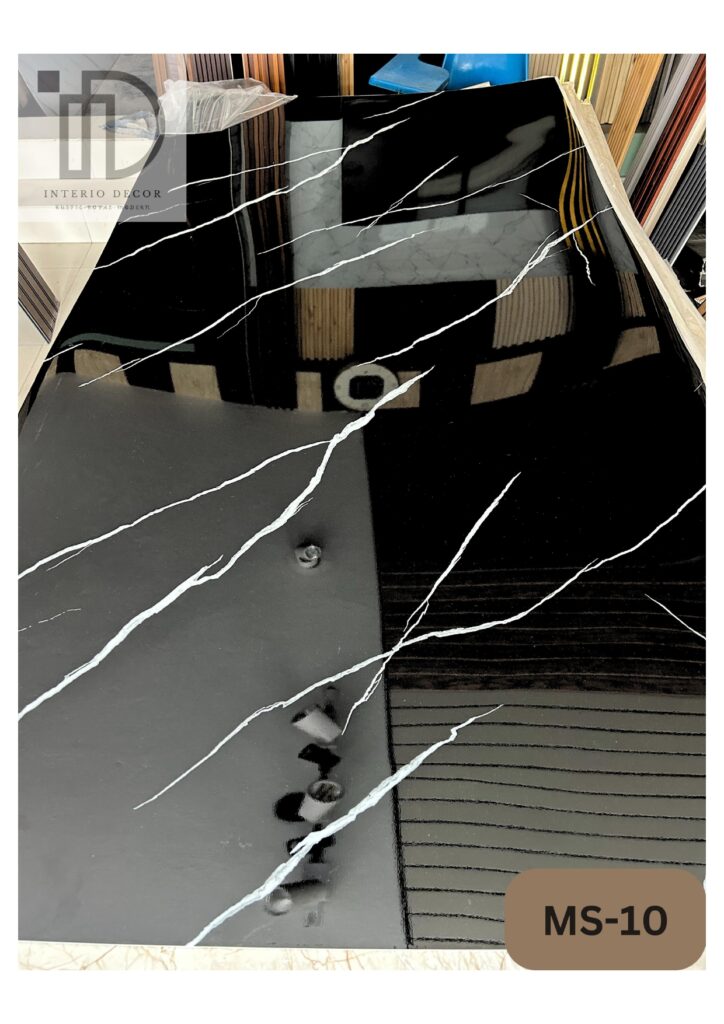

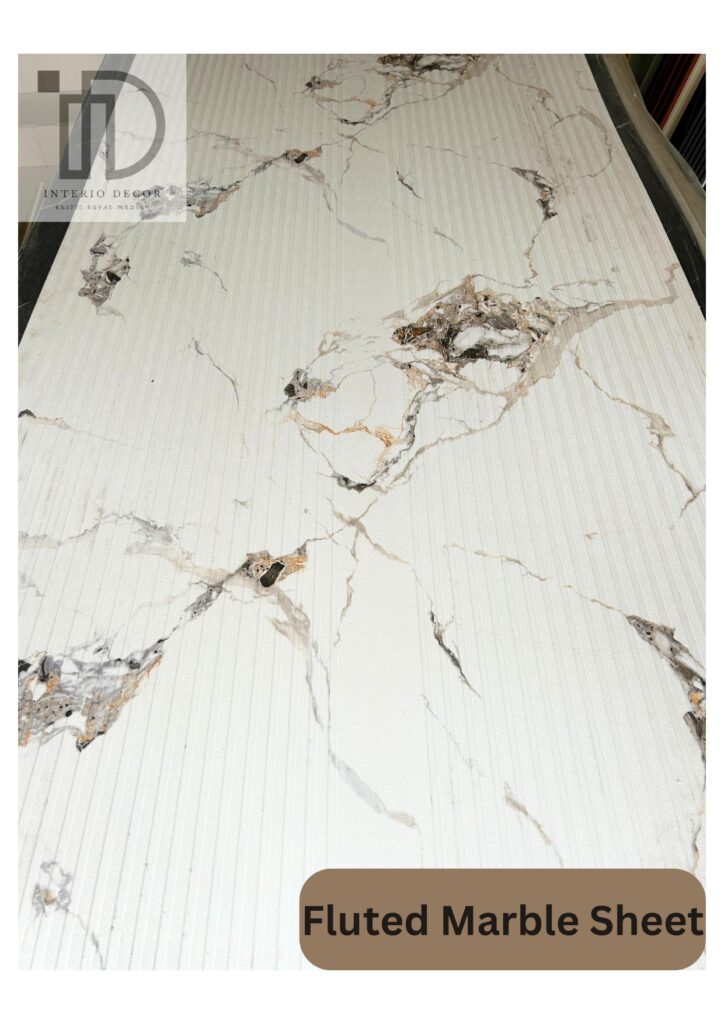

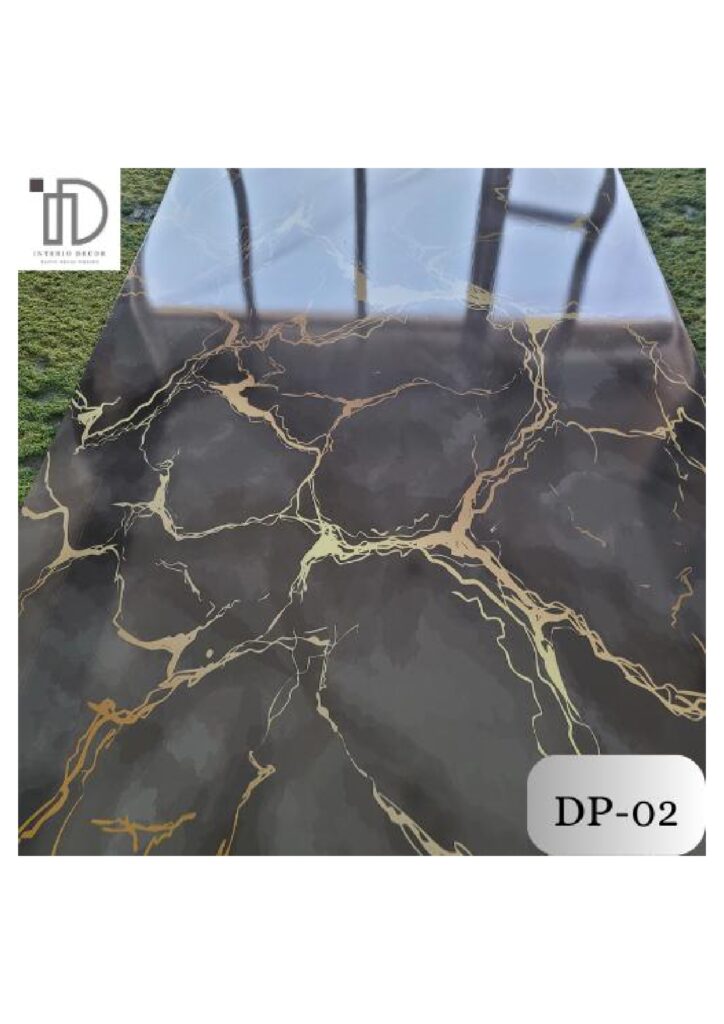

A UV Marble Sheet imparts an ultraviolet aesthetic, lending a refined and uncluttered appearance to interiors. Suitable for a variety of construction applications, especially flooring, it adds sophistication. Textile items can be employed to shield products or individuals from UV radiation. To achieve this effectively, the textile must possess the capability to resist UV transmission through its fibers or prevent radiation penetration through the fabric’s interstices. This necessitates UV-resistant fibers and a fabric structure with good optical transparency but low penetration of UV radiation.

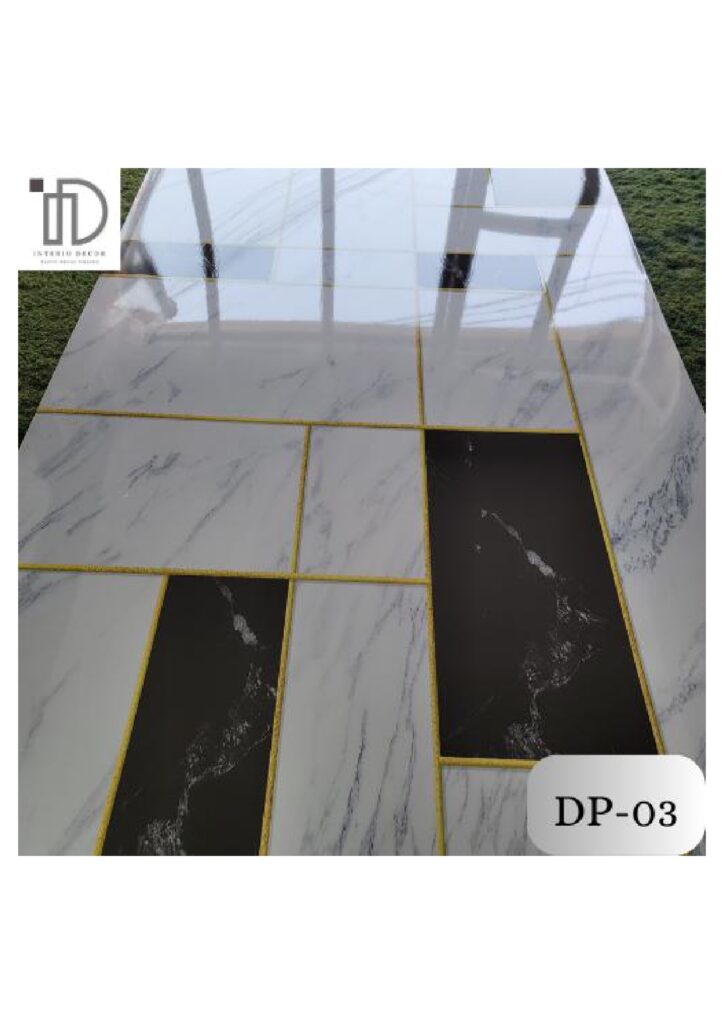

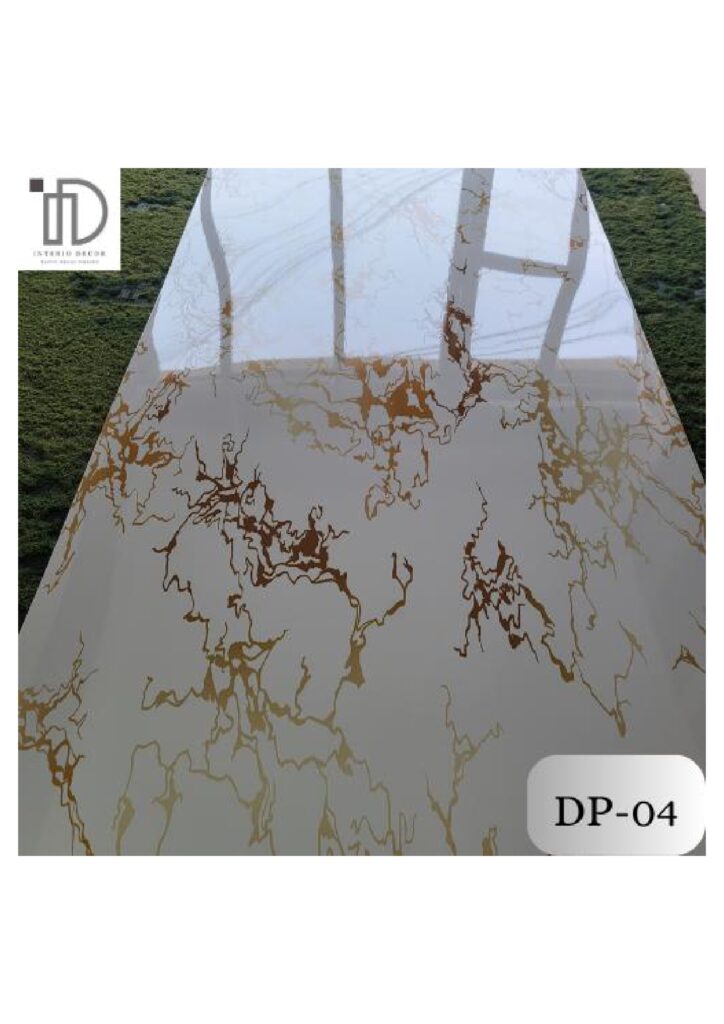

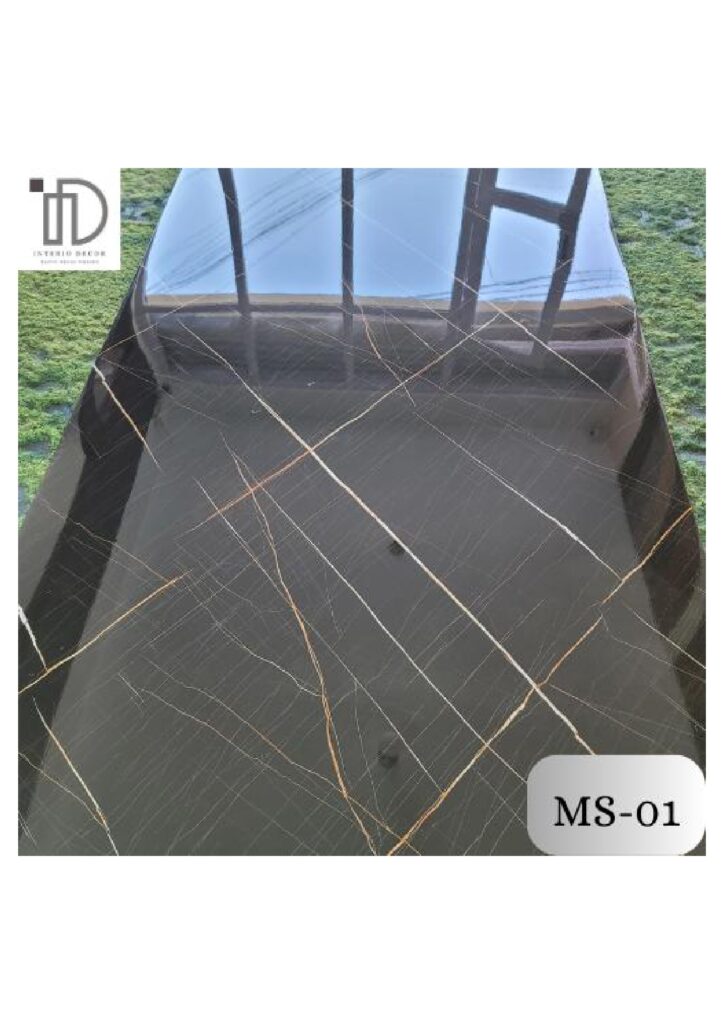

We belong to the distinguished group of organizations offering top-notch UV Marble Sheets. This panel is meticulously crafted using high-quality polyvinyl chloride and innovative techniques under the guidance of our experts. Widely utilized in residences, hotels, offices, and other spaces to create a captivating ambiance, the panel is available in various sizes and designs to cater to the preferences of our clients.

Features of UV Sheets

Ultraviolet Resistance: UV sheets are often designed to resist the damaging effects of ultraviolet radiation. This resistance helps prevent fading, discoloration, and degradation of the material when exposed to sunlight.

Enhanced Durability: UV coatings contribute to the durability of the sheets, making them more resistant to scratches, stains, and other forms of wear and tear. This can be particularly important for materials used in high-traffic areas.

Vibrant Colors: UV technology is sometimes used for printing and coating to enhance the color saturation and vibrancy of the sheets. This can be beneficial for applications where aesthetics are important.

Weather Resistance: UV sheets may have increased resistance to the effects of weather, making them suitable for both indoor and outdoor applications. This resistance can include protection against moisture, temperature fluctuations, and other environmental factors.

Easy Maintenance: The UV coating on sheets often makes them easier to clean and maintain. This is advantageous for applications where cleanliness and hygiene are essential.

Application Versatility: UV sheets can be used in various applications such as interior decoration, furniture, signage, and more. Their versatility makes them suitable for a wide range of design and construction purposes.

Customization Options: Depending on the manufacturing process, UV sheets may offer customization options in terms of colors, patterns, and finishes. This allows for greater flexibility in design choices.

Resistant to Chemicals: Some UV-treated sheets may exhibit resistance to chemicals, making them suitable for environments where exposure to certain substances is a concern.

Ultraviolet Resistance

Enhanced Durability

Vibrant Colors

Weather Resistance

East Maintainance

Application Versatility

Customization Options

Chemical Resistance

Applications of UV Sheets

Interior Decoration:

- UV sheets are often used in interior design for wall paneling, ceiling cladding, and other decorative elements.

- They can provide a sophisticated and modern look to spaces like homes, offices, hotels, and commercial establishments.

Furniture Manufacturing:

- UV-coated sheets are used in furniture manufacturing to create durable and visually appealing surfaces for tables, cabinets, and other furniture items.

- The UV coating enhances the resistance of the furniture to scratches, stains, and fading.

Signage and Display:

- UV sheets are utilized in the production of signage and display materials due to their vibrant colors, high resolution, and resistance to weather conditions.

- They are often used for outdoor signs, indoor displays, and promotional materials.

Retail Fixtures:

- Retail environments often use UV sheets for fixtures and displays to create visually appealing and durable showcases for products.

Construction and Architecture:

- UV sheets can be applied in construction for cladding, facade elements, and architectural details.

- They are chosen for their resistance to environmental factors and their ability to maintain their appearance over time.

Advertising and Marketing:

- UV sheets are employed in the production of promotional materials, such as banners, posters, and exhibition displays.

- The UV coating enhances the visual impact of printed materials and helps them withstand exposure to sunlight.

Industrial Applications:

- UV-resistant sheets may find use in industrial settings where exposure to UV radiation and harsh conditions is a concern.

- These sheets can be used for protective coverings, equipment panels, and other applications where durability is crucial.

Healthcare Settings:

- UV-resistant materials may be used in healthcare environments for surfaces that require easy cleaning and maintenance.

- The UV coating can contribute to the hygienic properties of the materials.

Automotive Interiors:

- UV sheets can be incorporated into automotive interiors for decorative panels, dashboards, and other components, providing both aesthetics and durability.

Advantages of UV Sheets

Ultraviolet Resistance:

One of the primary benefits is their resistance to ultraviolet (UV) radiation. UV-resistant coatings help prevent fading, discoloration, and degradation when exposed to sunlight, ensuring long-lasting aesthetics.Enhanced Durability:

UV sheets are known for their durability. The UV coating contributes to the material’s resistance to scratches, abrasion, and other forms of wear and tear, making them suitable for high-traffic areas.Vibrant Colors and High Resolution:

UV printing technology allows for vibrant and high-resolution graphics. This makes UV sheets ideal for applications where visual appeal and clarity of printed images are crucial, such as signage and displays.Weather Resistance:

UV sheets exhibit good resistance to weather conditions, making them suitable for both indoor and outdoor applications. They can withstand exposure to moisture, temperature fluctuations, and other environmental factors.Easy Maintenance:

The UV coating on these sheets makes them easy to clean and maintain. This is particularly advantageous for applications in spaces where cleanliness is a priority, such as healthcare settings and commercial environments.Customization Options:

UV sheets often offer a range of customization options, including various colors, patterns, and finishes. This versatility allows designers and manufacturers to create unique and personalized solutions.Quick Curing Time:

UV curing technology enables fast curing of the coating, reducing production time. This is especially valuable in manufacturing processes where efficiency and quick turnaround are essential.Chemical Resistance:

Some UV sheets exhibit resistance to chemicals, making them suitable for applications where exposure to certain substances is a concern. This is beneficial in industrial and laboratory settings.Versatility in Applications:

UV sheets find applications in diverse industries, including interior design, furniture manufacturing, signage, construction, automotive, and more. Their versatility makes them adaptable to various needs.Environmental Considerations:

UV curing is often considered an environmentally friendly process as it typically involves low or zero volatile organic compounds (VOCs). This can be an advantage for industries aiming to reduce their environmental impact.

Uses of UV Sheets in Nepal

In Nepal, UV sheets serve diverse purposes across multiple sectors owing to their versatile qualities. These sheets can be utilized in interior decoration, adorning walls, ceilings, and various decorative elements in homes, offices, hotels, and commercial spaces, thereby enhancing the overall aesthetics. In the furniture manufacturing industry, UV sheets offer an opportunity to create durable and visually appealing surfaces for tables, cabinets, and other furniture items, bringing a modern touch to Nepalese living spaces. Their application extends to the construction and architecture sector, where they can be used for cladding, facade elements, and architectural details due to their resilience against environmental factors.

Additionally, UV sheets find relevance in signage and displays, offering vibrant and weather-resistant solutions for businesses, markets, and promotional events in Nepal. Retail fixtures, advertising materials, and automotive interiors can also benefit from the properties of UV sheets, contributing to both visual appeal and longevity. Educational institutions and healthcare settings may incorporate UV-resistant materials for interior decor, furniture, and surfaces that require easy cleaning, ensuring a conducive and hygienic environment. Industrial applications, residential settings, and various other sectors in Nepal can explore the versatility of UV sheets to enhance both functionality and aesthetics according to specific needs and local conditions.